Micro LED technology can almost be considered the most advanced display technology that can be mass-produced currently. As a retailer, distributor, or integrator, if you want to customise a Micro LED display, what do you need to know? This article will tell you the answer.

Table of Contents

What is Micro LED Technology?

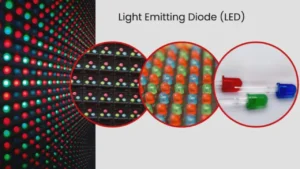

Micro LED technology uses tiny LED chips, typically ranging from 1 to 100 microns, as individual light-emitting display units and pixels. Compared to traditional SMD LED screens, Micro LED features smaller chip sizes and pixel pitches, which can deliver a higher definition display performance, and is suitable for various professional applications.

Pros of Micro LED Technology

High Brightness

When buying an LED display, brightness is one of the most important factors to consider. Due to its self-emissive feature, Micro LED is not blocked by an LCD panel in front, allowing it to achieve higher brightness.

Generally, indoor Micro LED TVs can reach around 3,000 nits (candelas per square meter), while those used outdoors can easily achieve 5,000 or even over 10,000 nits. Because of its tiny LED bulbs and highly efficient materials, micro LED technology is currently the brightest display technology available in mass production.

High Color Gamut and Grayscale

Color gamut refers to the range of colors a display device can show; it is generally represented by sRGB or Adobe RGB. Micro LED generally uses high-purity RGB chips, whose red, green, and blue peak wavelengths are well-defined, which enables the display can show a wider color gamut. Moreover, unlike LCD screens that need polarizers and backlights, the light loss of Micro LED is low, which shows more saturated colors.

Grayscale is the number of brightness levels a device can distinguish between black and white, typically expressed in bits. Thanks to the high-purity RGB, Micro LED can achieve 10–12-bit grayscale, which has smoother image transitions, while traditional LCD displays typically reach only 8–10 bits.

Small Pixel Pitch and High Resolution

Pixel pitch refers to the distance between two adjacent pixels on an LED screen. The smaller this value, the more compact the pixels, resulting in a clearer display. Compared to traditional outdoor LED screens with a pixel pitch of 3–10 mm, Micro LED features an extremely small pixel pitch, typically ranging from 0.1 to 0.5 mm.

Resolution refers to the number of pixels on a screen, which is determined by both the screen size and pixel pitch. Due to the extremely small pixel pitch, Micro LED can achieve high-definition display, typically at 2K or 4K. When Micro LED technology is applied to large commercial display walls, the screen resolution can even reach 8K.

Long Lifespan and Low Failure Rate

Lifespan means the operating time of a display until its brightness decays to a certain level. Typical OLED technology offers a lifespan of 10,000–30,000 hours, with relatively fast brightness decay, whereas Micro LED displays can last over 100,000 hours.

Moreover, Micro LEDs also have a very low failure rate. On one hand, compared to LCD, Micro LED does not suffer from burn-in even after long periods of display. On the other hand, Micro LED uses inorganic LED materials such as GaN and InGaN, which are resistant to high temperatures and light degradation, resulting in slow brightness decay.

Low Energy Consumption

Micro LED does not require an LCD backlight, which minimizes brightness loss from obstruction. Additionally, Micro LED uses highly efficient chips which made of GaN or InGaN, consuming less power than OLED screens at the same brightness.

Cons of Micro LED Technology

High Production Cost

The size of Micro LED chips is extremely small, which is approximately 5–50 μm, and each pixel needs to be controlled by an individual current; thus, their manufacturing is highly challenging. Besides, after fabrication, Micro LED chips need to be precisely transferred onto the display substrate, with each LED positioned accurately.

Furthermore, not only are fabrication and transfer challenging, but packaging and testing also require substantial equipment and labor costs, which make Micro LED very expensive. For example, Samsung’s 115-inch Class MICRO RGB TV is priced at $29,999.

The Yield Rate is Hard to Meet the Standard

Yield rate is the ratio of products that pass quality inspection to the total number produced. The higher the yield, the more consistent the production process. Due to the extremely small size of Micro LED chips, a large number must be transferred, making them prone to damage during the process.

Moreover, a single defective pixel can affect the display of the entire screen. Therefore, the yield of Micro LED is often relatively low, making mass production difficult.

Complex Manufacturing Process

The production process of an LED display includes chip fabrication, brightness testing, mass transfer, packaging, integration, and testing. For Micro LED technology, almost every step is significantly more complex than in conventional display technologies. For instance, a module contains millions of pixels, and each pixel needs to go through brightness and color testing.

Main Application Scenarios of Micro LED Technology

High-end TV

Some leading TV manufacturers, such as Samsung and Hisense, have already launched TVs based on Micro LED technology, while others, like TCL and Sony, are also developing it. However, due to the highly complex technology, Micro LED TVs are still extremely expensive, and the consumer market is mainly made up of high-end users, resulting in very low adoption rates.

In-vehicle Display

Micro LED technology has already begun early adoption in some high-end cars. For example, NIO, Volkswagen, and the Porsche Cayenne have started equipping their latest models with Micro LED pixel headlights. In the future, as the technology matures, Micro LED–based HUDs, smart cockpit displays, and transparent displays will also become a reality.

Professional and Innovation Field

Micro LED is also preferred in some professional areas due to its near-perfect performance, including high brightness, outstanding color performance, and extremely long lifespan. Currently, it has been used in some scenarios like control centers and exhibition halls.

In the future, it will also be applied in medical, AR/VR, and aviation fields. For instance, Apple, Meta, and Sony all have Micro LED AR–related products set to be released.

Commercial Display

Applying Micro LED technology to commercial displays, such as shopping mall facades, outdoor advertising screens, and corporate showrooms, can deliver excellent results. Even under direct sunlight, you can enjoy ultra-high clarity and vivid colors, as well as an even more immersive 3D display.

The development of Micro LED in the commercial sector is still ongoing, with applications expanding to an increasing number of locations. For example, Leyard’s Micro LED product series has been widely used in monitoring command centers, commercial centers, and other display scenarios.

Challenges and Future Trends of Micro LED

Standardized Manufacturing Process

Thanks to its outstanding performance, the Micro LED market is sure to expand further. At the same time, the production process of Micro LED displays needs to be scaled up to increase output and improve product quality.

This requires manufacturers to continuously invest manpower and resources in technological breakthroughs, including developing integrated systems and improving chip technology and packaging methods.

Reduce Production Costs

Ways to reduce costs include lowering raw material expenses and optimizing the production process. For example, manufacturers may experiment with higher-efficiency LED wafer materials during research and development. To reduce the cost of certain raw materials, some suppliers also built their own production lines. With technological advances, the price of Micro LED products has been gradually decreasing year by year.

Widely Popularized and Used in More Areas

With the maturation of the manufacturing process and declining production costs, Micro LED will gradually be adopted by more companies, retailers, and consumers, because it is currently nearly the most advanced display technology that can be mass-produced. In the future, Micro LED will have huge potential markets in entertainment, industrial, medical sectors, and other fields.

Micro LED, Mini LED, and OLED: What are the Differences?

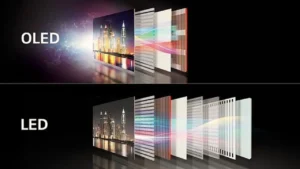

Working Principle

Micro LED, Mini LED, and OLED are currently among the most advanced display technologies in mass production. As mentioned, Micro LED features self-emissive micro pixels on the screen, while OLED is also self-emissive. In contrast, Mini LED combines an LCD panel with LED backlighting to display images.

Color Representation and Brightness

The three technologies all can deliver high grayscale, wide color gamut, and high resolution, with minimal differences in color performance. For brightness, OLED usually has under 1,000 nits due to its organic emissive materials. LCD panels block some light, so Mini LED brightness is also limited, generally staying below 5,000 nits. While Micro LED does not have such restrictions, and represents the display technology capable of achieving the highest brightness.

Lifespan and Maintenance Cost

The organic materials also limit the lifespan of the display, so OLED typically can be used for about five years, and it also carries a risk of screen burn-in. Mini LED screens have a longer lifespan, typically ranging from 50,000 to 80,000 hours. Micro LED has the longest lifespan among nearly all display technologies, and can be used for ten or even twenty years with nearly the lowest maintenance frequency and cost.

Application Scenarios

OLED is widely used in smartphones, smartwatches, and some TVs thanks to its ultra-high contrast, fine image quality, and ability to support foldable displays; Mini LED is mostly used in scenarios that require high brightness, such as in-vehicle displays and laptop screens.

Micro LED is mainly used in high-end scenarios such as premium conference rooms and large commercial displays due to current technological and cost limitations, but it holds tremendous growth potential.

FAQs

Is the Micro LED sensitive to temperature and humidity?

Generally speaking, Micro LED is far less sensitive to temperature and humidity compared with conventional LED displays and can operate normally within a range of –20°C to 60°C. Moreover, the LED chips made from inorganic materials have excellent humidity resistance, rarely failing due to moisture exposure.

However, it’s worth noting that high-humidity environments can still corrode electrodes and other components. When operating the display in such conditions, you should still take care to prevent moisture from entering the modules.

Does the Micro LED support local dimming?

Yes. More than this, each pixel in a Micro LED display is a self-emissive unit and supports independent dimming. Compared with Mini LED technology, which offers only hundreds or a few thousand dimming zones, Micro LED can achieve tens of thousands of zones, delivering the most exceptional dimming performance.

Can Micro LED technology be used in flexible or foldable displays?

In theory, Micro LED chips are tiny and structurally robust, which makes flexible and foldable displays possible. However, due to the inability to achieve sufficiently flat flexible substrates, along with the high complexity of mass transfer and packaging, flexible or foldable Micro LED displays are unlikely to reach mass production in the next few years.

IvanLED: Your Reliable Partner in LED Display Customisation

Are you looking for a manufacturer that can customize LED displays? If so, IvanLED is definitely a suitable choice for you.

IvanLED is a professional manufacturer with over ten years of experience in LED display production. We can customize LED displays in various sizes and pixel pitches, and even transparent, flexible, and foldable screens. Whether it’s for shopping malls, museums, bus stations, or concert stages, we are experienced in producing displays for all types of applications.

If you have any questions about LED displays, feel free to contact us!