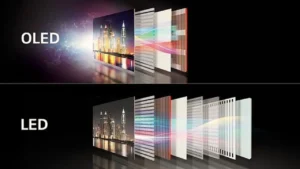

In today’s world, you can see LED screens in most modern displays, such as microphones smartphones, etc. Professionals in electronics and display technology must know what type of materials have been used in manufacturing. You need to understand some major features of LED screens that are responsible for their performance and efficiency.

Table of Contents

Core Components of LED Screens

Professionals in electronics manufacturing and display technology need to have a comprehension of the core components of LED screens. You can find the main components below:

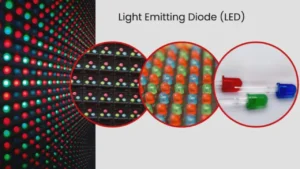

Light-emitting diodes (LED’s)

The most fundamental light sources in LED screens are LED’s. When an electric current passes through them, they emit light and hence you see the colors on the display. The screen’s brightness, color accuracy, and energy effectiveness are all determined by the quality and efficiency of LED’s.

LED Modules

Multiple LED’s are arranged on one board in LED modules. These modules are the led screen (or screen building blocks) and they can scale as well as customize based on the size of the display they are used in.

Display Panels

The assembled units are called display panels and these house LED modules. They give the structural framework and protective casing for the LED’s and other electronics it comes with. The materials of the panel determine how the screen is manufactured for durability, heat, and aesthetic purposes.

Materials Used in LED Screen Manufacturing

Semiconductor Materials in LED’s

Gallium-Based Compounds

Typical LED chemistry relies on gallium compounds such as gallium arsenide (GaAs) and gallium nitride (GaN). Using GaN, blue and white LED’s can be produced, whereas GaAs is used for infrared LED’s. They also have direct bandgap properties that enable efficient light emission.

Indium Gallium Zinc Oxide (IGZO)

Indium gallium zinc oxide (IGZO) is an inorganic crystalline semiconducting glass. It provides a high electron mobility at low leakage current which is suitable for thin film transistors for display technologies. IGZO also helps improve display resolution and cut power consumption for more efficient and reliable LED screens.

Substrate Materials

Sapphire

The uniqueness lies in the fact that sapphire is so commonly used as it is so hard and chemically stable. It also provides a stable support structure that supports the epitaxial layer. Nevertheless, its thermal conductivity is rather poor affecting heat dissipation in LED devices.

Silicon Carbide (SiC)

The excellent thermal conductivity of SiC helps improve heat dissipation in LED devices. Additionally, the lattice constant of the epitaxial layer is suitable for that of gallium nitride (GaN), resulting in a higher layer quality.

Silicon

Insect size requires a cost-effective substrate of this level that is widely used in the semiconductor industry.’ Although, the defects in the epitaxial layer due to the lattice mismatch between silicon and GaN can degrade LED performance.

Encapsulation and Lens Materials

Epoxy Resins

Mostly epoxy resins are used in the encapsulation of the LED because of their excellent adhesion and greater transparency. They provide good adhesion to the LED chip and the other components.

Silicone Materials

LED encapsulation requires low-stress material with high UV resistance and aging resistance, which are silicone materials. Silicone resin has light transmittance proportional to the luminous intensity and efficiency of LED devices.

Optical Lenses

The optical lenses are made of optical grade plastics or glass and focus or spread the light. The wall candles are important for regulating light distribution and producing a desired visual effect.

Conductive Materials

Metals for Electrodes

Conductive materials are important in LED screen manufacturing for electrical performance. Gold and copper are often used for their excellent conductivity, as electrodes. There is high reliability in unstable environments with gold, but copper is cost-effective. Copper however has a higher oxidation level reducing its life in certain conditions.

Transparent Conductive Oxides

Vital too are transparent conductive oxides (TCOs). Both ITO and FTO are widely used because of their transparency and conductivity. As these TCOs allow light emission and electrical conductivity simultaneously, transparent electrodes become possible.

Phosphor Materials for Color Conversion

Yttrium Aluminum Garnet (YAG) Phosphors

However, YAG phosphors are often employed in producing white LED’s. Blue light from the LED chip is absorbed and yellow light is emitted. The remaining blue light mixed with the yellow will create the white light. The amount of YAG phosphor being used can be varied to change the color temperature of the white light.

Quantum Dots

Semiconductor nanocrystals which emit light when excited are called Quantum Dots. They are used in LED screens to improve color accuracy and brightness. The Quantum Dots emit red and green pure light when blue light from the LED chip excites them. The result is an expanded gamut and more vivid colors on the display.

Heat Dissipation Materials

Thermal Interface Materials (TIMs)

You can use Thermal Interface Materials (TIMs) to bridges microscopic gaps between LED components and heat sinks to increase thermal conductivity. There are many forms, such as pastes, pads, or tapes. The selection of the suitable TIM results in effective heat transfer to avoid overheating and possibly damage to your LED screen.

Heat Sinks

Heat sinks are designed to absorb and dissipate the heat of LED components. Aluminum, copper, and some other materials are very good in thermal conductivity. Heat sinks increase the surface area of the LED which helps you to transfer the heat away from the LED to the point where the temperature is at its optimal level for continued use and the life of the LED display is extended.

Protective and Structural Materials

Encapsulation Materials

Silicone and epoxy resins are the main encapsulation materials which you can used for the LED chips. Silicone has good thermal stability and moisture resistance for high-power LED’s. A kind of epoxy resin that offers good adhesion and good economy, are commonly used in outdoor LED lighting.

Housing and Frames

You can use aluminum alloys mainly for housing and frames on account of their lightweight and unique properties. They provide an excellent framework for LED displays: secure and aesthetically pleasing. The selection of the material is of utmost importance for the achievement of maximum performance and life span of LED screens.

Perovskite Materials

Due to the excellent light-emitting properties of perovskite materials, you will find them interesting and helpful in the development of LED screens. High color purity and efficiency of such materials allow them to be used in advanced display technologies. These solutions are process able and allow you to use them easy and cheap production methods. Perovskite-based LEDs (PeLEDs) have drawn the attention of researchers to examine their applications in displays, sensors, and lighting.

The tunable bandgap of perovskites allows for the display of vivid colors and high brightness. Studying to improve the stability and performance of perovskite materials and placing them into commercial applications is ongoing research.

Two-Dimensional Materials

The new 2D materials, including graphene and TMDs, have completely changed LED screen manufacturing. Because of their unique properties, ultra-thin, flexible, and efficient displays can be made. For example, micro LED’s based on 2D materials have been developed that can achieve high pixel density and small sizes. Thus, these advancements enable the manufacturing of lightweight and durable LED screens with better performance and user experience. This marks a very significant step in display innovation with the packaging of 2D materials with LED technology.

FAQ’s

How do thermal interface materials and heat sinks contribute to the longevity and efficiency of LED displays?

Heat management equipment (Heat sinks, Thermal interface materials (TIMs), Heat pipes, etc.) are important in LED displays. Heat transfer can be enhanced by TIMs by filling up microscopic gaps between the components. LED junction is often operating in the heat sink environment where the heat is being absorbed and dispersed from the LED junction.

How do MicroLEDs differ from traditional LED’s in terms of materials and performance?

MicroLEDs are microscopic LEDs that emit their light directly, thus no backlight is needed. Usually, they are fabricated from inorganic materials like gallium nitride (GaN), as such materials have higher brightness and efficiency than organic materials used in traditional LED’s. The results from this composition mean longer lifespans and reduced screen burn-in.

Conclusion

To the professionals in electronics and display technology, it is important to understand what approach is required to manufacture LED screens. Each part plays a role in helping the screen’s performance, efficiency, and sustainability. If you are looking for an LED screen of high quality, consider Ivanled. Contact us now as we have a wide range of products to suit your needs.