LED display production involves many steps ranging from material preparation, assembly to testing. In this guide, we will explore some fundamental aspects of LED display manufacturing process.

From choosing the right material, module assembly, encapsulation, cabinet assembly to quality control processes – you will find all information on LED display production right here.

Let’s explore these processes in detail.

Table of Contents

Raw Material Preparation

Every LED display manufacture begins with the right parts. You must pick high-quality:

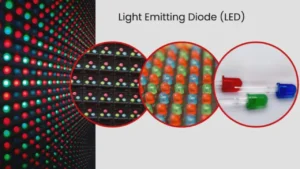

- LED chips

- Driver ICs

- Circuit boards

- Connectors

These parts control your screen’s brightness, color accuracy, and longevity. If you choose cheap parts, your display might break down or perform poorly.

Also, pay attention to where you get these LED screen materials because quality varies among suppliers. Always ask for test data and certifications before committing. When you invest in quality materials it means your display will last longer and need fewer repairs. That in turn saves you time and money.

Moisture is a big threat to LED components, and thus, the parts should be dehumidified before proceeding any further. This process is called dehumidification treatment of the parts so that moisture does not damage your components during soldering.

You can use a special oven to heat the components at a controlled temperature to dry the moisture without affecting the sensitive chips. If you miss this step, trapped moisture may boil during the process of soldering and damage your board.

Surface-Mount Technology (SMT) Process

· Solder Paste Application

You start the surface-mount technology (SMT) process by applying solder paste on the printed circuit board (PCB). The paste comprises small solder balls suspended in flux, a chemical that ensures good soldering by cleaning the metal surfaces.

A stencil aligned over the PCB board helps the paste to deposit right onto the solder pads.

Accuracy is key at this point. Misalignment can result in defects such as solder bridges or open circuits. To achieve uniform results and sharp definition, you should use high-precision stencil printers. The stencil spreads the paste over the board evenly using a metal squeegee.

Moreover, the thickness of the paste layer plays an important role in the quality of the connections. Too much can cause short circuits, while too little will lead to weak joints. Modern machines automatically control thickness as well as pressure for uniformity across all the pads.

After the application, you should conduct an inspection. Automated Optical Inspection (AOI) checks place, volume, and coverage of the paste on the board. If errors are caught at this point, it can save you from expensive mistakes in the later stages of the process.

· Component Placement

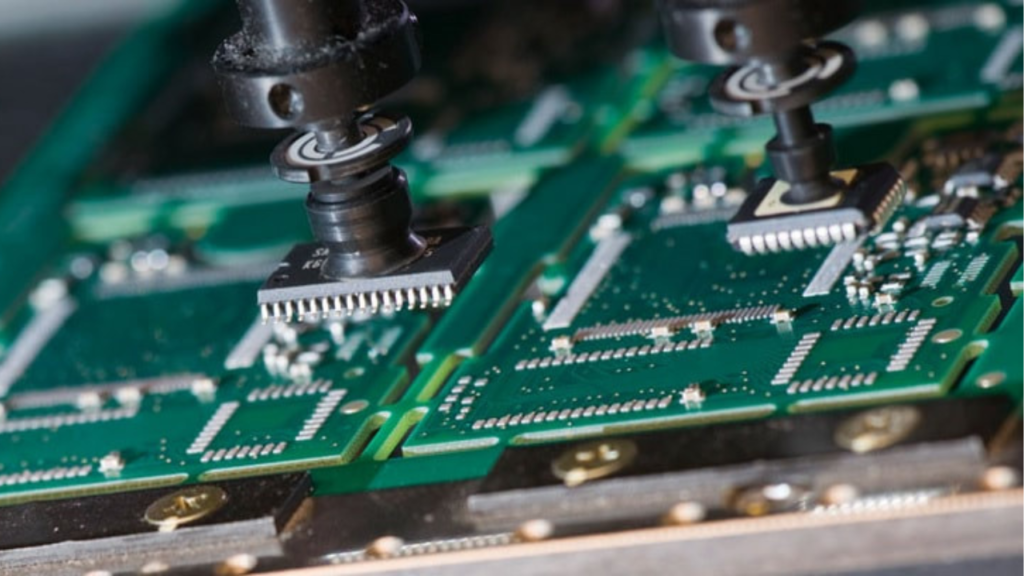

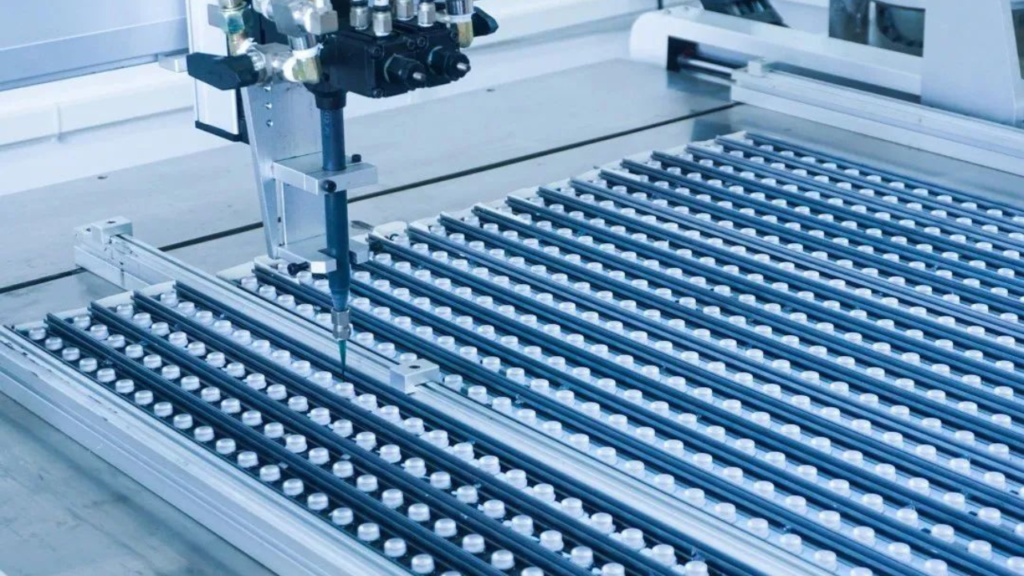

After the paste application, boards go through a part placement process. High-speed pick and place machines place surface-mount devices (SMDs) on the PCB. These machines use vacuum nozzles to pick up and place every component accurately on where you applied the paste.

Each orientation of the components must align with the design specifications of the LED display. Modern machines use vision systems that help to inspect the alignment before and after placement. This is to ensure proper polarity and position, especially for polarized components such as diodes and capacitors.

Components are in reels, trays, or tubes and auto fed into the machine. The machine reads the component data, aligns it using cameras, and places it within milliseconds. There can be thousands of placements in a single minute.

Once placed, components remain in position because of the tacked solder paste. However, they are not yet electrically connected.

· Reflow Soldering

Reflow soldering is the stage that you fix components to the PCB board permanently. Here, you pass the board through a temperature-controlled reflow oven, typically divided into several zones, which are preheat, soak, reflow, and cooling.

In the reflow phase, the solder paste undergoes melting, causing the formation of a mechanical and electrical connection between the leads of the components and the pads of the PCB. You should gradually increase the heating to ensure that the paste melts completely but does not damage the board or the components.

Moreover, you need to carefully program the oven temperatures based on the materials and component density of each board. The goal is to achieve complete reflow across all the joints while avoiding solder balling, bridging or shifting of components.

As the board comes out of the oven, it cools fast. As a result, this cooling helps to harden the solder and keep the parts safe. If not heated well, problems like cold solder joints, holes or ‘tombstoning’ (one side of a component comes off the board) can occur.

· LED Chip Placement

LED chip placing is a specialized part of SMT in display manufacture. These chips are put on a substrate with great care, as their placement directly affects display quality. Machines with sub-millimeter precision are used to place each LED onto specified pads.

Bonding material or conductive adhesive, depending on design, will ensure solid electrical contact between the LED and the board. You can apply heat-curing or UV-curing methods to harden the adhesive after placement.

Once mounted, you should run a light-on test to check function, brightness, and color. Any faulty LEDs are marked or removed. Since displays have thousands of individual LEDs, early detection of faulty chips helps improve overall yield and efficiency.

· Initial Testing

The reflow soldering and LED chip placement processes are immediately followed by initial testing. Here, you subject the assembled board to basic functionality checks. The objective is to catch obvious defects at this stage before proceeding to the following steps which are more complex. This includes verification of solder joints, component placement, and electrical continuity.

You begin the testing using Automated Optical Inspection (AOI) system. The board is scanned with the aid of high-resolution cameras in these machines, and the image obtained is compared to the reference design. If there is any deviation from the reference design, whether a component is misplaced, solder bridges, or there are some missing parts, it will flag the output for review.

Some manufactures conduct In-Circuit Testing (ICT) at this stage too. It checks if each part works correctly by making use of electric signals from test probes. ICT helps spot open circuits, short circuits, and parts that do not work. It saves time during later troubleshooting.

Furthermore, for LED displays, you can carry out a light-up test. You power every LED briefly to check its brightness, color, and response. If a pixel does not light or show the wrong color, you mark it for repair. The sooner you detect problems, the more smooth and efficient the assembly process will be.

Encapsulation and Protection

Encapsulation and protection is yet another critical stage when making LED display. This process in the LED display manufacturing process involve 3 main stages.

· AOB Encapsulation

AOB encapsulation is critical in protecting the fragile LED chips and components on the display board. It covers the assembled LEDs as well as the circuit areas with a protective resin or epoxy. It creates the encapsulant which in turn protects the sensitive parts from physical damage, dust, and any type of environmental contaminant.

The material you use for encapsulation should be transparent to allow maximum light output with adequate mechanical support. It should also acts as an insulator against moisture and electrical interference which can lead to short circuits or corrosion.

AOB encapsulation ensures that the LEDs maintain regular brightness and color over time.

Additionally, you should apply the encapsulation carefully so that there are no air bubbles or gaps because the presence of these gaps will reduce the protective effect. You can use precision dispensers and controlled curing processes to attain a smooth, uniform coating. This step is essential both in terms of prolonging the lifespan of the display and keeping it operating optimally under any adverse condition.

· Conformal Coating

Conformal coating is the extra layer of protection over the encapsulated board. It is a thin polymer film and closely it conforms to the surface and covers all components and traces. In this way, it becomes difficult for moisture, dust, and chemical contaminants to get in and cause corrosion or any electrical failure.

There are different types of conformal coatings including acrylic, silicone, or polyurethane with all having unique advantages. Your selection depends on the conditions in which the display will operate and requirements for durability. For instance, silicone coatings are suitable for outdoor displays since they have highly resistant to heat and humidity.

You can apply the coating by spraying, dipping, or brushing. After application, the coating cures into a hard flexible protective layer. This extra protection ensures reliable operation of the LED display in any weather conditions and environment.

· Waterproofing

Waterproofing is important for LED displays, especially outdoor LED displays. It involves sealing all the joints, edges, and any vulnerable area to ensure that no water penetrates inside. This protection ensures the display is safe from humidity or even accidental splashes.

You seal using silicone gaskets, rubber seals, or special waterproof adhesives. These filler materials are used to fill gaps between modules and cabinet components creating a tight enclosure. This in turn prevents penetration of moisture into the sensitive electronics.

Waterproofing also increases the screen’s ability to keep out dirt and other particles. It helps with the overall IP rating, which is a standard way of measuring how well something is protected from solids and liquids. Higher IP ratings means a durable display even in tough conditions.

Module Assembly

There are many types of LED modules. As part of the stages in the LED display manufacturing process, it is important to know the type of module you will be using.

As a matter of fact, in the LED display production, the module assembly involves:

· Back Shell and Mask Installation

Now you start to build up the display module. This involves adding the plastic mask and back shell. The mask covers the LED surface, shapes the pixels, and has an anti-glare property. The back shell sandwiches everything together and also serve as protection for the inner parts.

You should align everything properly. The mask should be a good fit that does not obscure any of the LEDs. Use screws, clips, or snaps to fasten the parts together. If you rush this stage, the display might appear uneven on your display or fall apart during use.

· Aging Test

After complete assembly of the module, you should perform an aging test. This includes lighting the display for hours or sometimes days at a very high voltage and brightness level so as to stress the components and reveal any hidden faults.

Cabinet Assembly

With the module ready, now it is time to assemble LED display cabinet. They key processes here include assembly and aging tests. Let’s explore what happens in this LED production stage:

· Assembly Process

At this stage, you assemble the cabinet that houses the modules, power supplies, fans and cables. You should ensure that everything fits properly to guarantee performance of the display.

Next, you attach the modules to a metal frame using screws or magnetic locks and then connect with a signal cable, power supply, and control card.

· Aging Test

Run another aging test, but this time with the full cabinet. Check the power distribution, heat dissipation, and if it’s really running as it should in real working condition, so that in case something has to go wrong, there is still time for fixing.

Calibration and Quality Control

· Color and Brightness Calibration

After you have built your cabinet, concentrate on calibration. LED chips vary slightly in color and brightness, thus, the purpose of calibration is to ensure all pixels are uniformly acting. You can use cameras and sensors to measure light output and then adjust the signal for matching of all LEDs.

· Environmental Testing

You should perform environmental tests. This means subjecting the cabinet to heat, cold, vibration, and humidity. These tests imitate what happens in real life and they help you to fine-tune design flaws before the display is shipped.

Final Inspection

Before you pack, each part should be inspected. Examine the screen for dead pixels, any color shifts, or scratches. Ensure every screw is tight and every cable attached is fixed. It is a last chance to catch issues.

Also, carry out a thorough functional check if video, text, images are all displayed as it gives you peace of mind. If the display passes through this stage, then it’s ready to go live.

Conclusion

As you can see, LED display manufacturing involve many steps. In most cases, LED display manufacturers may adopt unique technologies to produce their screens.

As your LED display manufacturer in China, we use the latest technology to produce world’s no.1 screens in the market. For all your LED screens from China, contact us now.